Industrial Magnets For Aggregate & Materials Processing

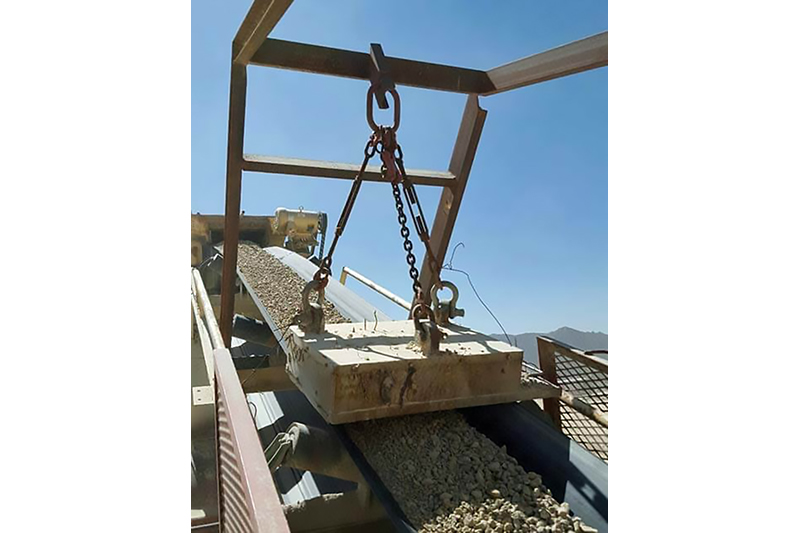

Cities are the hub of large operations that make use of heavy equipment to create stone products for construction. Here, earth-movers and belt conveyors work together with machines designed specifically for crushing aggregate into different sizes depending on its purpose. Aggregate facilities also exist which process reclaimed concrete as recycled materials – a smart way to reduce landfill waste whilst providing valuable resources for future building projects! At these plants featuring overhead magnetic separators, metal is efficiently removed from each portion of reused concrete before it can be repurposed in new structures and roads.

I tip my hat to your firm. It’s not every day something this good comes along. Our MKS-4000 Tow Behind Magnetic Sweeper covers 6.2 miles 5 days per week and it just works. The fabrication is amazing, the construction is incredibly solid. We are truly impressed.

The merchandise delivers as promised and continues to keep our downtimes minimal – That’s critical in our industry.

Aggregate is a Valuable Commodity

According to the USGS, in 2006, crushed stone was 1.72 tons value at nearly $14 billion dollars. Most of the U.S. aggregate (30%) is used for non-residential buildings, followed by highways (25%) and housing (25%). Additionally, 2.9 million tons of Portland cement worth $21.9 million was recycled, and 1.6 million tons of asphalt concrete worth $11.8 million was recycled; both by crushed stone operations. More of both materials are recycled by construction and demolition firms that were not part of the USGS survey. That is a lot of rock!

Now, think about the value of material your facility can crush in a single hour of operation. Now consider what it costs you in terms of lost time when a crusher has to be taken offline because it or a conveyor has been damaged by a piece of ferrous metal.

After the crushing machine, an overhead separator magnet might be the most valuable piece of equipment at an aggregate processing plant. Overhead separators help ensure that the crushing equipment and conveyors run continuously without stoppage, helping your processing facility avoid costly repairs and hours of lost production.

Overhead Separator Magnets Guarantee That Aggregate Keeps Moving

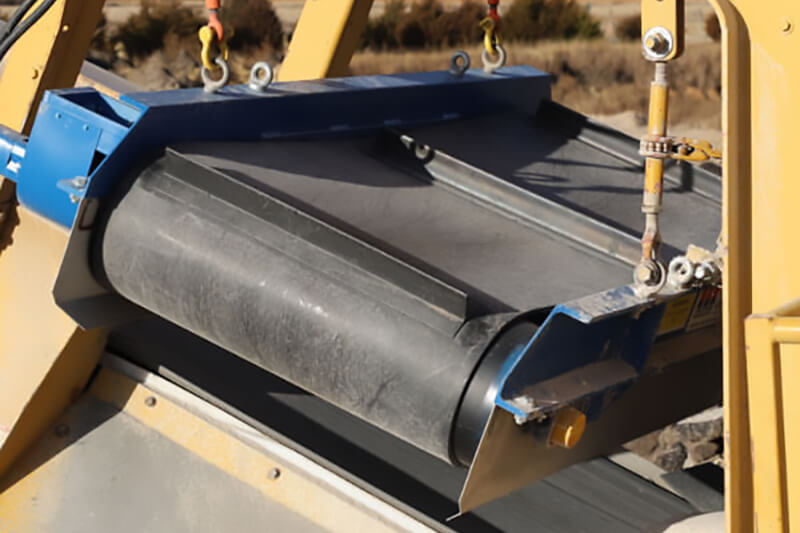

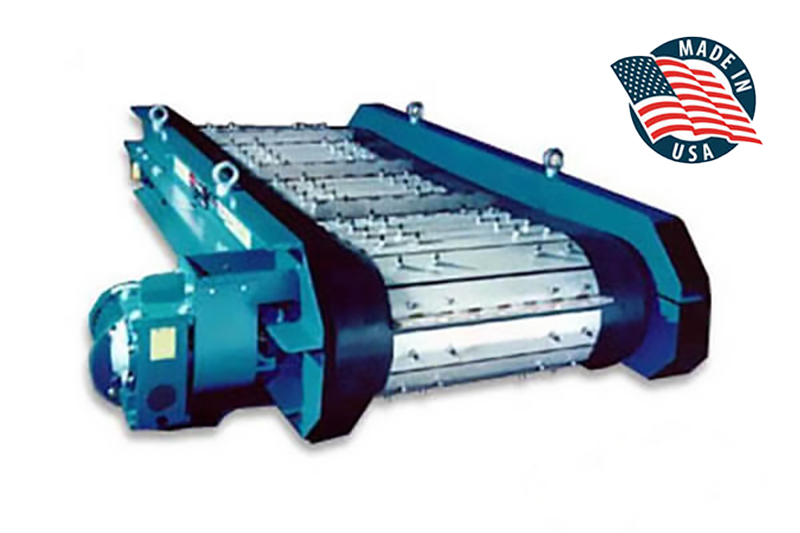

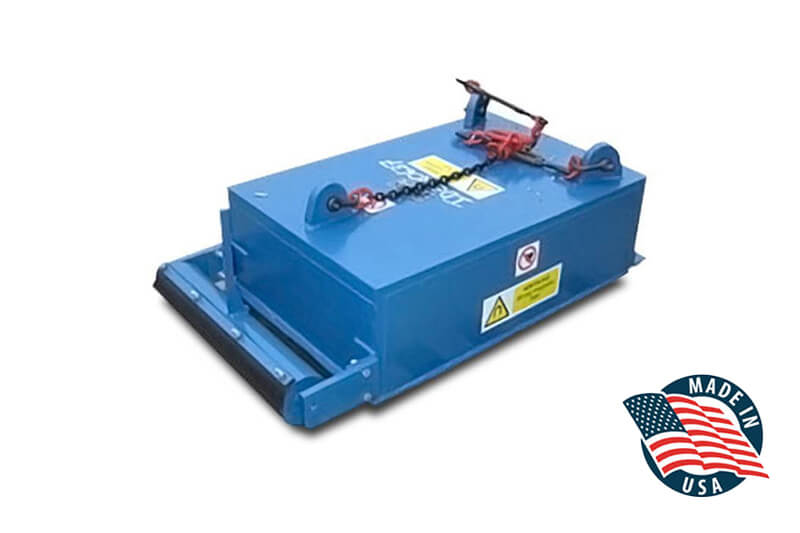

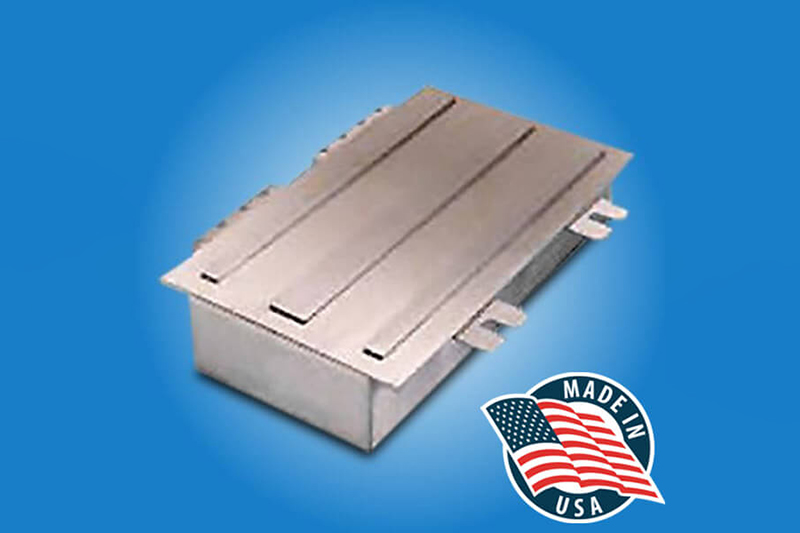

Our permanent suspension magnets are designed specifically to remove large pieces of tramp iron from the material destined for the crusher. Our separators have a working gap ranging from 1”-18”, with over 30 sizes available, thus we have a model and size for every application.

Our overhead separator magnets routinely operate for over 10,000 hours with zero maintenance!

What makes this possible? Exclusive to the industry, Shields Tri-Polar Magnetic Circuitry virtually eliminates peripheral magnetic leakage and directs the magnetic field straight down, thus creating a stronger magnet. These magnets have a lifetime guarantee on magnetic strength.

These magnets are 30% stronger than magnets of equal size, and also more powerful to many sizes of electromagnets. As a result, our overhead separators are capable of removing more metal than competitors’ separators and can be used reliably in more extreme conditions. The end result is that virtually all metal is removed from the material flow preventing damage to other equipment involved in the process, improving uptime, and maximizing output.

Use our handy overhead separator criteria form to help us determine the size of your overhead separator.