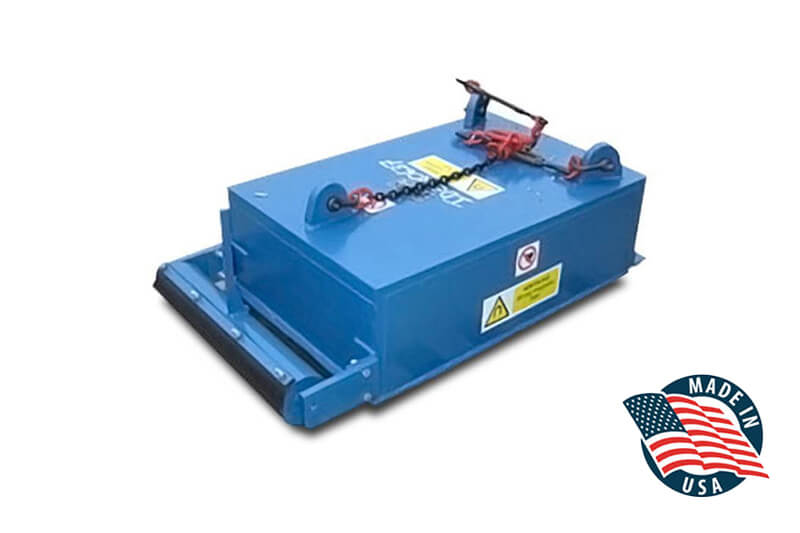

Stationary Separator Magnets

Starting From $1750.00 for smallest size unit

We Have Over 30 Sizes of Stationary Separators. Many In Stock!

Use Our Quick and Easy 3-Step Process:

Step 1. Click on the “Start Criteria” button below and provide the requested information (if you don’t know it all it’s ok).

Step 2. We will contact you to let you know your criteria was received and collect any additional information needed.

Step 3. We will provide a quote including specs, lead time and cost within 24 hours.

Description

Permanent Suspension Magnet Details

Permanent Suspension Magnets are designed specifically for the extraction of occasional tramp iron from material being processed on the conveyor belt, vibratory feeder or gravity chute. These overhead magnets are constructed using Grade 8 high power ceramic magnetics and require no electricity, unlike electro type units.

- Overhead magnets available for conveyor widths from 12″ up to 72″

- Stationary magnetic separator works with any depth of product flow from minimal to deep

- Suitable for low or high volume processing

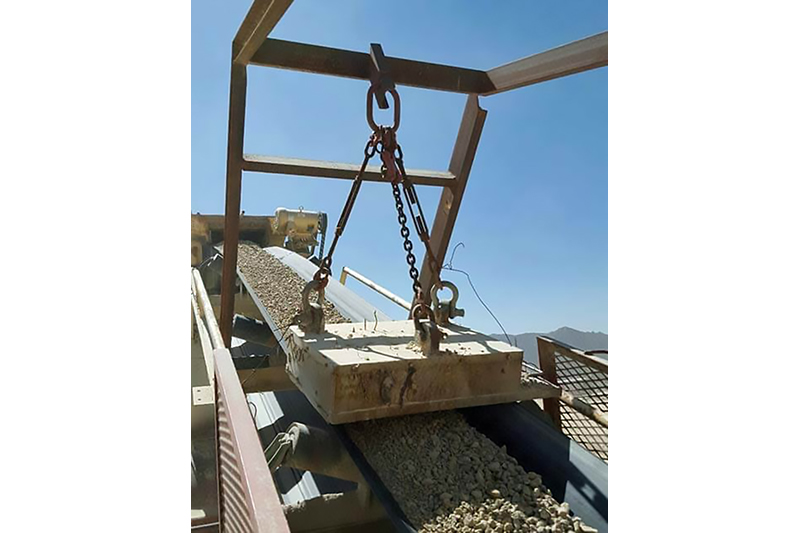

- Mounts parallel over conveyors or in-line over head pulleys

- Housing constructed of welded stainless steel, strongest used in industry

- Impervious to moisture, fire and corrosion making them suitable for the harshest of environments

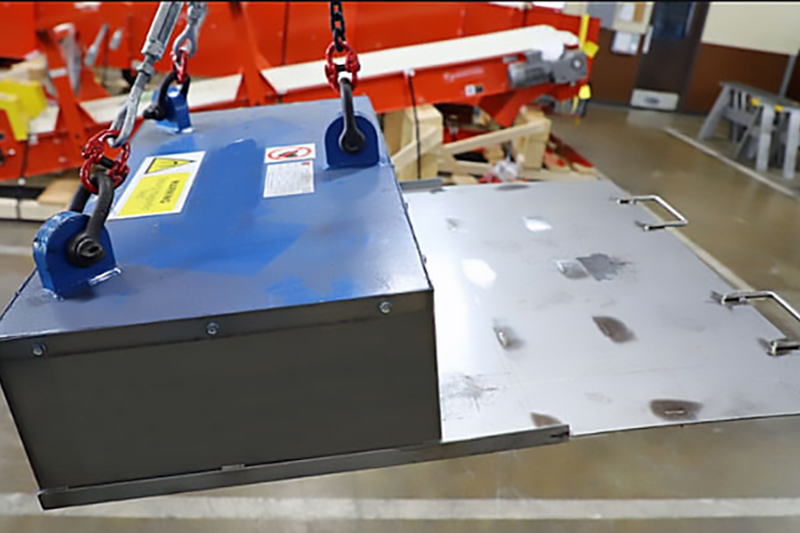

- All magnets equipped with a belt stripper or slide tray for easy, safe cleaning and a free set of adjustable sling chains for proper installation and suspension.

The magnetic separator, usually a rectangular pattern, is suspended over the material being conveyed, while the ferrous material is extracted and held against the face of the magnet until manually cleaned off.

For safety and ease of cleaning, swipe arms or slide trays are standard on all magnetic separator units to assist in cleaning without having to touch the tramp metals. And when comparing to electro magnets, they are less expensive to purchase, operate and are virtually moisture, corrosion and flame proof.

Typical applications for the use of Permanent Suspension Magnets include removal of iron from coal, stone, fertilizers, recycled asphalt, stag, gypsum, ores and similar materials where contamination by tramp iron is occasional and continuous separation is not essential and the primary purpose is processing machinery protection. These overhead magnets can be mounted either horizontal or inclined over the head pulley. All stationary magnets are fitted with a set of adjustable suspension chains designed to suit application and attach to suspension lugs. Preferred installation position is above the head pulley where the burden is spread out and the material is in virtual suspension as it is discharged from the conveyor.

Magnetic Separators can be mounted on a variety of structures, including runway beams (using a trolley for suspension and movement) or A-Frame structure. Size availability covers the entire range of conveyor widths and material burden depths to 25″, depending on material being separated.

WARRANTY

A Limited Lifetime Warranty on the magnet system is offered, against loss of magnetic strength, when used under normal operating conditions. Magnet systems are available in over 110 models to match any conveyor width, from 12″ to 84″ or burden depth to 25″, depending on the material being separated. With as many as 50 units always in stock at our warehouse, including many of the popular sizes, they are ready for immediate delivery.

Tri-Polar Circuitry Delivers Improved Magnetic Strength

Exclusive to the industry, our magnetic separators utilize tri-polar magnetic circuitry. This eliminates most peripheral magnetic leakage and directs the magnetic field straight down, improving and increasing the strength compared to equivalent sized magnets. This technology is not available from any other magnet system manufacturer in North America. Magnetic intensity in excess of 400-500 gauss at the recommended working gap retained permanently when used under normal operating conditions.

With the Tri-Polar© Magnetic Circuitry as part of SHIELDS/MASTERMAG’s larger Permanent Industrial Magnet Series, Permanent Magnet Technology will never be the same. As a direct result of this new technology, peripheral magnetic leakage is all but eliminated, directing the magnetic field straight down and creating a stronger magnet. These magnets are approximately 30% more powerful than the competing units of the same size and equivalent or superior to many sizes of electromagnets.

As a result of this increase in strength and the potential for use in extreme applications – Manganese Wear Impact Plates are included as standard.

Companies Rely on Shields Stationary Separator Magnets

Stationary Separator Magnet Product Applications:

- Aggregate Processing

- Coal Mining

- Power Station

- Paper Mills

- Plastics Processing

Additional information

| Weight | 350 lbs |

|---|---|

| Dimensions | 30 × 15 × 18 in |

| Model |