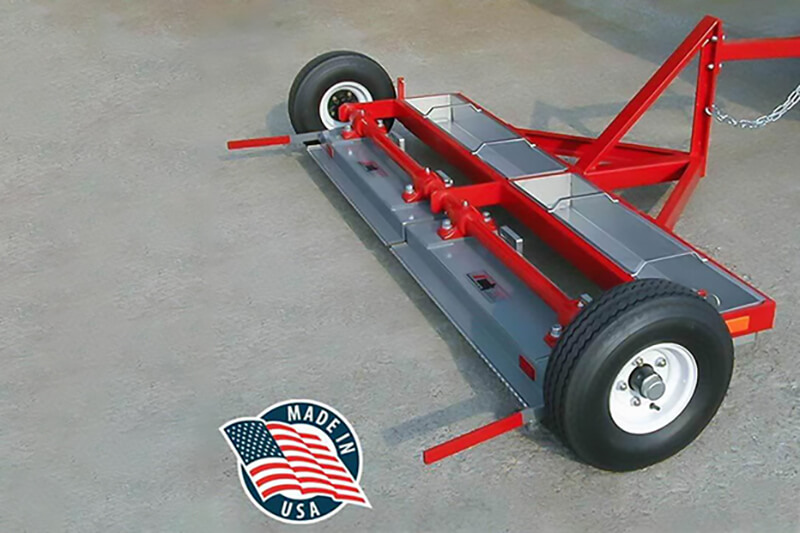

MKS4000: Airfield/Runway Tow Behind Magnetic Sweeper

Heavy-duty professional grade towable sweeper for roads and airfields. Features state-of-the art materials and highest quality commercial grade magnets available. Available in 48″, 60″, 72″ 84″ and 96″ width versions.

Call (805) 642-4408 with any Questions or to Order!

![]() Government: Also Available Under GSA Schedule 51V , Contract number is GS-06F-0046N Learn about our government capabilities (including NAIC and PCS numbers)

Government: Also Available Under GSA Schedule 51V , Contract number is GS-06F-0046N Learn about our government capabilities (including NAIC and PCS numbers)

International Buyers: Click here to find your global distribution partner.

Description

Designed for roads and airfields, the MKS4000 heavy-duty professional grade towable magnetic road sweepers are made to last. This device is constructed with state-of-the-art materials, including the highest commercial grade Grade 8 Permanent Magnets, to ensure our tow-behind magnets remove the maximum amount of ferrous metal debris.

- The Magnetic Tow-Behind Road Sweep meets USA Government military specifications under MIL-S-29174B.

- Tow behind magnetic sweepers are the most effective method of removing ferrous metal from concrete grooves!

- 2″ clearance at 13 mph with road magnets in sweeping position, 5″ clearance with magnets in traveling position.

- Actual sweeping widths of 48″, 60″, 72″, 84″, and 96″

- Attracted material is easily dumped into 4-1/2″ deep retainer pans eliminating time-consuming trips to dump sites.

- Trailer-type frame constructed of heavy gauge steel for long-lasting performance and durability.

- 4.80 – 8 / Tire & Wheel Assembly, Load Range B, 4 Ply Rated Trailer Tire on 8″ x 3.75 (5) Lug White Steel Trailer Wheel, Capacity: 590 pounds @ 60 PSI.

- HIGH SPEED rated trailer tire. OPTION: FOAM FILLED TIRE – Same assembly; with pneumatic tire permanently filled with foam for flat resistance.

- Replacement parts available

- Tow-Behind Magnetic Sweeper available in Red or Green

- Unconditional Product Performance Guarantee

Assembly

- Lift the main frame assembly and install the tire and rim assemblies onto the hub assemblies. Secure with (10) lug nuts.

- Attach the tongue to the main frame assembly using (6) 1/2 – 13 x 1 1/4 hex head bolts, flat washers, lock washers and nuts. Tighten all nuts and bolts securely.

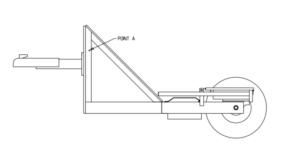

- Attach the fire safety chain to the tongue at point A using (1) 1/4″ Quick-Link.

- Determine the proper height of the tow ring (or ball coupling) and attach to the tongue using (4) 1/2 – 13 x 1 3/4 hex head bolts, flat washers, lock washers and nuts. When the sweeper is correctly attached to the towing vehicle, the main frame and magnet faces will be level.

How to Use

The MKS4000 Magnetic Tow Sweeper is ready for use when the magnets are turned to the sweeping position (Fig 1).

In this position, the magnets are held at a 2½ inch sweeping height, providing effective tramp metal retrieval at speeds up to 13 miles per hour.

To clean the magnets of attracted tramp metal, first turn off the tow vehicle engine, and engage the emergency brake. Rotate the magnets to the unload position (Fig 3).

Using the hinged stripper plate handles, open the stripper plates, and dump the tramp metal into the retainer pans. The retainer pans eliminate the need to dump the tramp metal on the ground where it must be picked up again. They also eliminate excessive trips to a dump site, thus allowing greater productivity.

Before closing the stripper plates insure that there is no tramp metal stuck to the magnet face. Return the stripper plates to the closed position, and insure that the stripper plate handles are fully seated against the front of the magnets.

To continue sweeping, rotate the magnets back to the working position. Use caution during this procedure. If the magnet handle is released before the magnet is fully rotated damage can result to the magnet or to the sweeper frame.

When the sweeping task is completed, rotate the magnets to the travel position (Fig 2) and lock them in place using the linchpins provided. In this position the Magnetic Tow Sweeper may be moved at speeds up to 55 miles per hour on smooth surfaces.

Because it has no springs, the Magnetic Tow Sweeper is designed for use primarily on smooth surfaces. If it is to be used on unimproved surfaces, the sweeping speed must be slowed to prevent damage to the wheel spindles.

The Magnetic Tow Sweeper should be stored with the magnets in the sweeping position to eliminate the safety hazard of having the magnetic surfaces exposed.

Maintenance

After assembly of the Tow Sweeper, check all fasteners for tightness, including the shaft collars that hold the magnets in place. Periodically check for loosened nuts and bolts.

The Tow Sweeper is shipped with all bearings greased. Periodically check the 2-inch pillow block bearings and add grease as needed using a good quality lithium based grease. Periodically check the wheel bearings and hub assemblies and add grease as needed using a good quality wheel bearing grease.

Before each use, check the tires for proper inflation. Maintain tire pressure as indicated on the tire wall.

Small amounts of ferrous material will be attracted to the front, back and sides of the magnets. After each sweeping operation, manually remove all attracted material.

Compare Our Tow Behind Magnets

| Product | 3-in-1 | MKS4000 | MKS 5000 |

|---|---|---|---|

| Max Lifting Height | 3″ | 5″ | 4″ |

| Sweeper Weight | 60-110 lbs | 450-650 lbs | 650-950 lbs |

| Sweeper Widths | 36-96″ | 60″, 72″, 84″, 96″ | 60″, 72″, 84″, 96″ |

| Cleaning Method | Top Mounted Release | Release Trays/Catch Pan | Gas, Spring Assisted Levers |

| Terrain | Any | Smooth | Any/Pavement/Dirt/Broken Concrete |

| Price Range | $695-$1250 | $4500-$6500 | $5900-$7500 |

Customers

Request Pricing on an MKS4000 Tow Behind Magnet

Additional information

| WIDTH | 48-INCH — PRICE INCLUDES FREIGHT, 60-INCH — PRICE INCLUDES FREIGHT, 72-INCH — PRICE INCLUDES FREIGHT, 84-INCH — PRICE INCLUDES FREIGHT |

|---|