You just sat down to enjoy your Saturday breakfast – hot coffee, orange juice, toast, hash browns, sausage, and an egg-white omelet. Everything seems perfect until you take a bite of sausage. Something doesn’t seem right. Instead of a burst of smoky flavor, you pull a metal fragment out of your mouth. You check the rest of your meal for metal scraps. You end up throwing away the rest of your breakfast, worried about how much metal you may have eaten without noticing.

Finding metal contaminants in your food isn’t only “annoying” and unappetizing. It also poses serious risks to your health, especially if ingested. This unfortunate scenario recently became a reality for a national breakfast food company, which resulted in a massive product recall. There is something that could’ve prevented this public relations nightmare – accurate and dependable ferrous metal removal and separation. Magnetic Separators and Belt Magnets eliminate the presence of ferrous and some non-ferrous metals in a process flow, or as a packaged item, and allows you to remove the contaminated product.

Shields Magnetics Offers Magnetic Separator Solutions for the Food Industry that Keep Products Safe for Consumers

In efforts of damage control, the breakfast food company tried hard to protect the brand, and attempted to assure customers of their commitment to safety. However, this incident will likely have a lingering impact on the company’s reputation. This all could have been avoided if they had been using the proper magnetic separation equipment on their processing line.

Metal is the most common foreign material found in food processing. This is why it’s so important for companies to detect and remove these hazardous contaminants before the product is packed and shipped. When contaminated food reaches the open market, it can have devastating consequences for both the company and their customers.

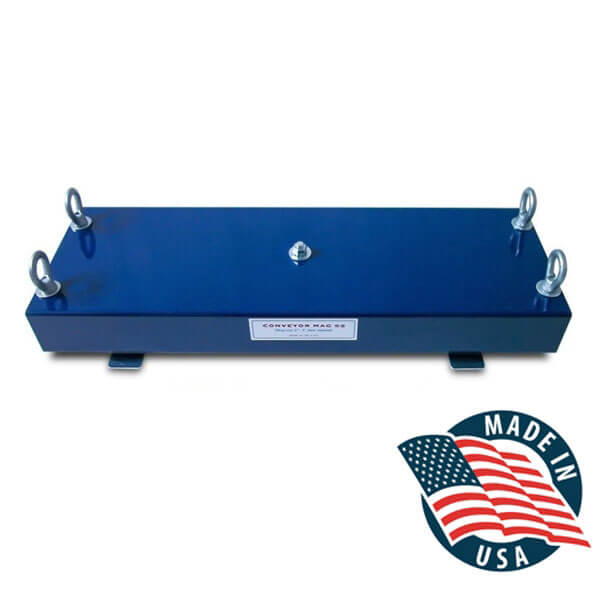

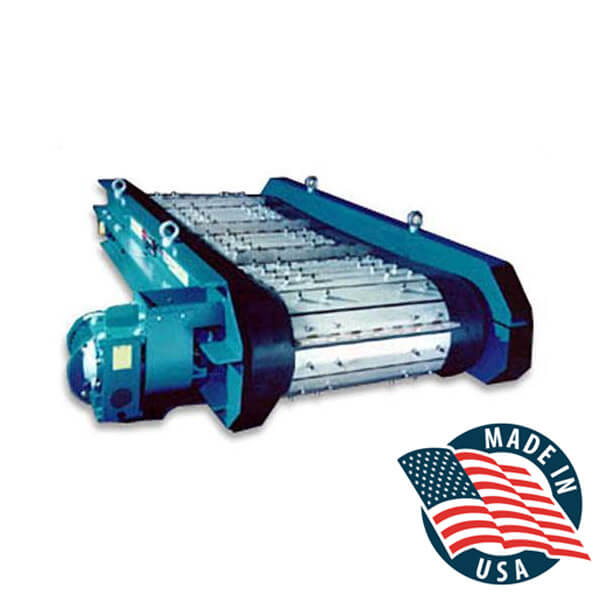

Using the right magnetic applications (belt magnets, conveyor magnets, drum magnets) (along with regular testing and maintenance) is the only way to keep food products pure and safe for consumers. Shields Magnetics belt magnets are used in food plants to ensure the purity of your product, while protecting your valuable machinery from damage. Having magnetic separator applications that can handle both fresh and frozen meats is crucial to the success of businesses in the food industry.

Our cross belt magnetic separators are perfect for applications in either in-installations where space is limited. “One Stop” sizing means many of our conveyor magnets are custom-made for the unique needs of your application. Our larger Stationary Separators use “Tri-Polar Magnetic Circuitry, which eliminates peripheral magnetic leakage so all of the force field is directed straight down to where it’s needed most. This is exclusive to the industry.

For more information about which magnetic separators are best for your application, please contact Shields Magnetics Co. to speak with a sales representative. We look forward to hearing from you and discussing how our magnetic separation products can help your business succeed!